Ray & Son Heating & Air Conditioning has served Nashville, Valdosta & the surrounding areas with honest, reliable comfort and performance solutions since 1965. One call solves it all.

Ask us about how to qualify for a $2,000 tax credit for a heat pump – LEARN MORE

Subject to credit Approval. Minimum finance amount of $1,000.

Contact us for details.

Contact us for details.

Ray & Son Heating & Air Conditioning has been in business for 59 years! We are honored to have served our customers and community with our quality HVAC services. Feel free to watch our introductory videos below to see what makes Ray & Son Heating & Air Conditioning so special.

We look forward to the future of Ray & Son Heating & Air Conditioning and will continue providing the best Georgia HVAC service to our loyal customers in the coming years.

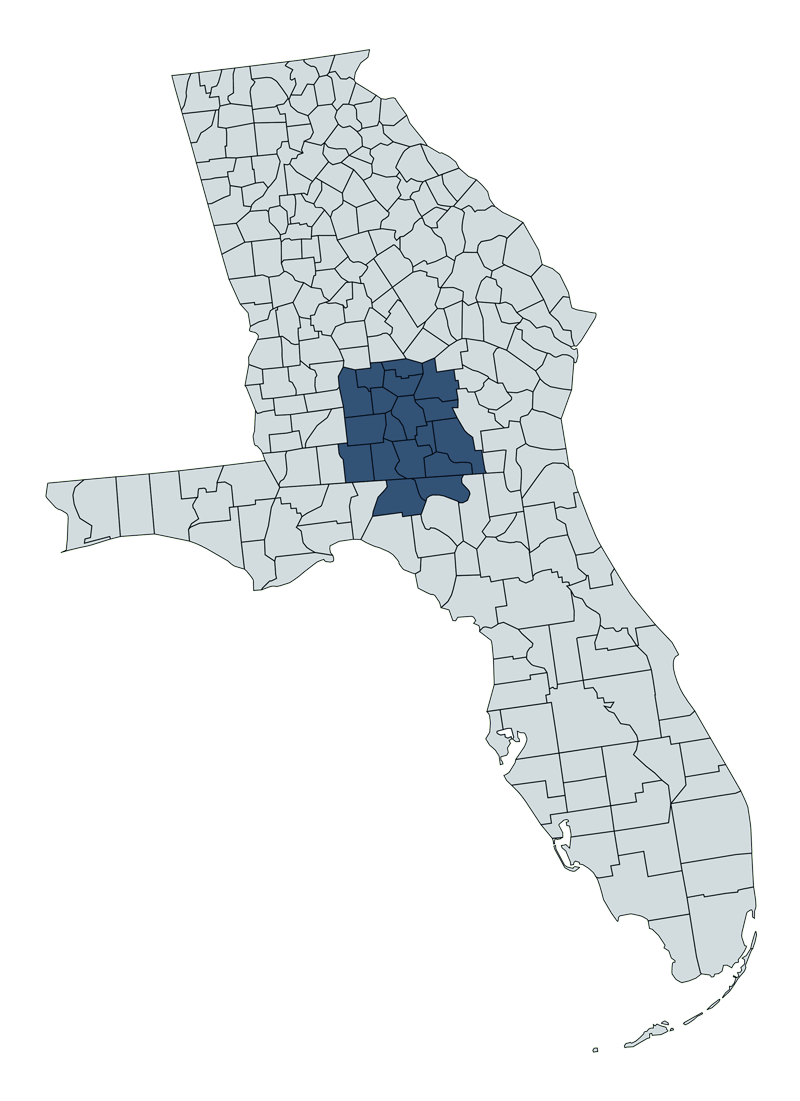

AC Service, AC Repair, Air Conditioner Repair, Air Conditioning Installation & Air Conditioner ServiceValdosta, GA, Clyattville, GA, Quitman, GA, Hahira, GA, Nashville, GA & Adel, GA

Family owned, Ray & Son Heating & Air Conditioning is your premier provider of a wide range of HVAC and plumbing equipment and services in Nashville, Valdosta & the surrounding areas. Specializing in an impressive list of options, we encourage you to give us a call at (229) 215-8223. You’ll always speak with a live and knowledgeable member of our staff. Let us put our extensive experience, expertise, and resources to work for you. Our technicians are fully licensed, bonded, insured, NATE-certified, and BPI-certified, and we make regular training updates our priority.

Expert Heating and Cooling in Nashville, Valdosta & the surrounding areas

Professional HVAC Repairs, Maintenance, Replacements & New Installations Nashville, Valdosta & the surrounding areas

As a Carrier Factory Authorized Dealer, Ray & Son Heating & Air Conditioning has received top distinction as a President’s Award Winner. We offer free estimates and a “try it” for a year special on new and replacement heating/cooling equipment.

Whether you’re in need of installation, upgrades, repair, or maintenance, we are qualified in every aspect of temperature control, from WiFi thermostats and duct services to geothermal systems, air quality accessories, and so much more.

Ray & Son Heating & Air Conditioning provides for residential and commercial needs, helping you to achieve maximum efficiency, reliability, and longevity from your essential systems. Let us introduce you to the benefits of solar panels, automated controls, attic insulation, permanently installed standby generators, home performance testing, and a company dedicated to your best interests. At Ray & Son Heating & Air Conditioning, we stand behind our work with a 100% satisfaction guarantee. Where Service is Our Business and Quality is a Way of Life!